Designed by Daniel Tobin & Jamie Perrow of Urban Art Projects and the Plaza by Liam Proberts of Fairweather Proberts, Cadway and specifically myself, were given the difficult tasks of taking the complex design and producing accurate and complete documentation in order to realise this design.

Working with the Structural Engineers, Robert Bird Group - Lance Barton, strict construction tolerances were given that were part of the design constraints.

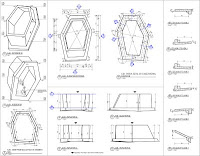

I then took these design constraints and constructed a highly robust Revit Family with over 70 parameters and numerous complex formulas (conditional statements, trigonometry and algebra). By creating parameters and using the API to calculate the true lengths of the edges of the hexagonal rings we were able to automate a lot of the shop drawing creation for the precast concrete elements. Within Revit we were able to directly and automatically extract weights and volumes to supply to the Structural Engineer for calculation.

Unfortunately, it wasn't all straight forward. Early in the design process I had to go through a number of iterations of my family whilst the construction technique was established. That is, which sections were Precast Concrete and which sections with Cast in-situ. The main issue being that the cast in-situ was a different colour to the precast concrete which wasn't a desired architectural outcome.

From there the Lighting Designers, Norman Disney and Young became involved and we worked with them to set out recessed lighting locations directly in the precast pieces themselves and documented their exact locations.

The Structural Engineers calculated 3 lifting points for each piece that simplified the lifting process so the natural centroid of the piece was already correct when lifted by the crane and lowered into position.

From here it was a process of placing all the individual hexagons and adjusting their many parameters to suit the concept design. As we were using Revit, as we placed the elements more and more of the documentation was also being completed. We were given tolerances for the spacing of the pieces to work with and then for every piece we supplied 12 coordinates to locate the precast members onsite (6 vertices internally and externally). Every single piece was different in shape and the internal faces of the precast members were completely faceted so the Revit family had to completely triangulate the faces.

Finally once all these pieces were placed, we then had to specifically model up the 4 different entrance frames which also had a steel framed core. We supplied the centroid points of the void spaces to the structural engineer and produced shop drawings for the many segments that then framed the doorways.

.jpg) The final stage to be completed is the entire plaza level which should now be well underconstruction to immitate the Giants Causeway.

The final stage to be completed is the entire plaza level which should now be well underconstruction to immitate the Giants Causeway.If anyone has any questions please don't hesitate to post a comment. I hope some find this information useful or interesting.